Introduction

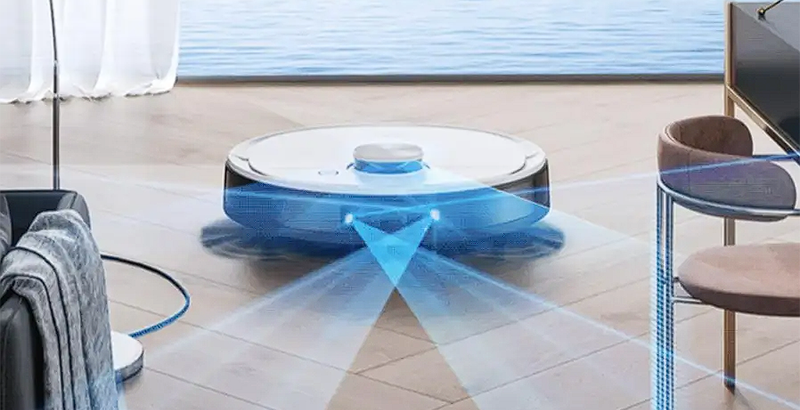

In the realm of robotics, LiDAR (Light Detection and Ranging) is playing a crucial role in enhancing obstacle detection and navigation. By providing detailed 3D mapping, LiDAR enables robots to operate safely and efficiently in complex industrial environments.

LiDAR in Robotics

LiDAR sensors create high-resolution 3D maps by emitting laser pulses and measuring their reflections. This data allows robots to perceive their surroundings in three dimensions, enabling them to detect and avoid obstacles effectively. For instance, a robotic arm used in an assembly line can utilize LiDAR data to navigate around obstacles and interact with other machines without collisions.

Applications in Industrial Robotics

LiDAR-enhanced robots are employed in various industrial applications, including material handling, inspection, and assembly. In a warehouse setting, LiDAR-equipped robots can autonomously navigate aisles, avoiding obstacles such as stacks of goods and other machinery. In manufacturing, robots can use LiDAR to ensure precise placement and assembly of components, minimizing errors and improving efficiency.

Benefits of LiDAR in Robotics

The primary benefit of LiDAR in robotics is its ability to provide accurate, real-time spatial data. This enhances the robot’s ability to navigate complex environments and perform tasks with high precision. Additionally, LiDAR’s effectiveness in diverse lighting conditions ensures reliable performance in various operational settings.

Challenges and Solutions

Challenges in utilizing LiDAR for robotics include the need for robust data processing and the integration of LiDAR with existing robotic systems. Advances in computational power and data fusion techniques are addressing these challenges, improving the feasibility of LiDAR in robotic applications.

Conclusion

LiDAR is significantly enhancing robotic systems in industrial settings by providing detailed 3D mapping and obstacle detection. Its ability to improve navigation and task performance makes it a valuable asset in modern robotics.