Introduction

Autonomous drones equipped with LiDAR technology are transforming industrial inspections by providing accurate and detailed 3D mapping. LiDAR enhances the ability of drones to navigate and inspect complex environments safely and efficiently.

LiDAR’s Impact on Drone Inspections

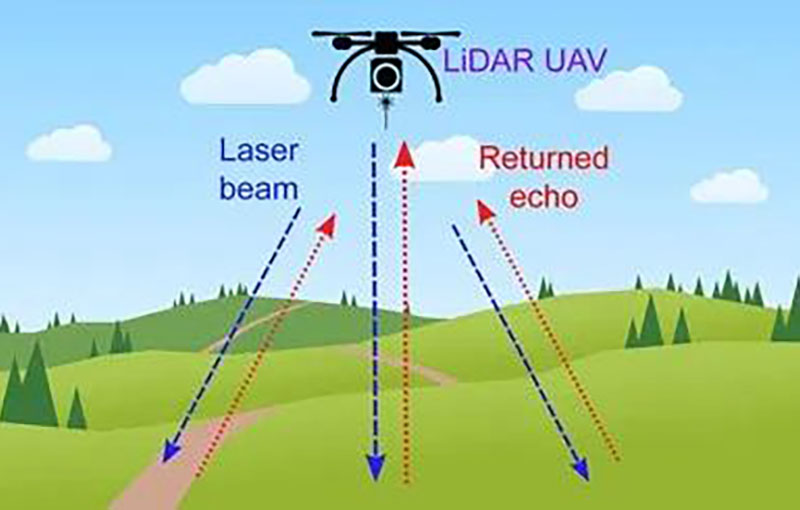

LiDAR sensors mounted on drones generate high-resolution 3D maps by emitting laser pulses and measuring their reflections. This data allows drones to perform detailed inspections of industrial infrastructure, such as pipelines, power lines, and buildings. For example, a drone equipped with LiDAR can survey a large industrial site, detecting obstacles and collecting data for analysis.

Benefits for Industrial Inspections

LiDAR-equipped drones offer several benefits for industrial inspections, including improved accuracy, efficiency, and safety. The detailed 3D maps generated by LiDAR allow for precise measurement and analysis of infrastructure, while the drone’s mobility enables access to difficult-to-reach areas.

Challenges and Solutions

Challenges in using LiDAR for drone inspections include the need for high computational power and data storage. Advances in drone technology and data processing solutions are addressing these challenges, making LiDAR-equipped drones more practical for industrial inspections.

Future Trends

The future of LiDAR in drone inspections includes advancements in sensor technology, data processing, and drone capabilities. These developments will enhance the efficiency and accuracy of industrial inspections, providing more valuable insights.

Conclusion

LiDAR technology is revolutionizing industrial inspections by enabling autonomous drones to perform detailed surveys and obstacle detection. Its impact on accuracy and efficiency makes it a key tool for modern industrial inspection processes.