LiDAR (Light Detection and Ranging) technology has become a valuable tool in the mining industry, offering precise, three-dimensional data that enhances operational efficiency, safety, and environmental management. By providing detailed information about terrain, stockpiles, and mine infrastructure, LiDAR helps mining companies optimize their operations, manage resources effectively, and ensure safety in challenging environments. This article explores how LiDAR is transforming mining practices and the benefits it brings to the industry.

Enhancing Mine Surveying and Mapping

Accurate surveying and mapping are critical in mining operations, and LiDAR technology provides high-resolution data that improves these processes. Traditional surveying methods can be time-consuming and limited by challenging terrain, but LiDAR offers a more efficient and detailed approach.

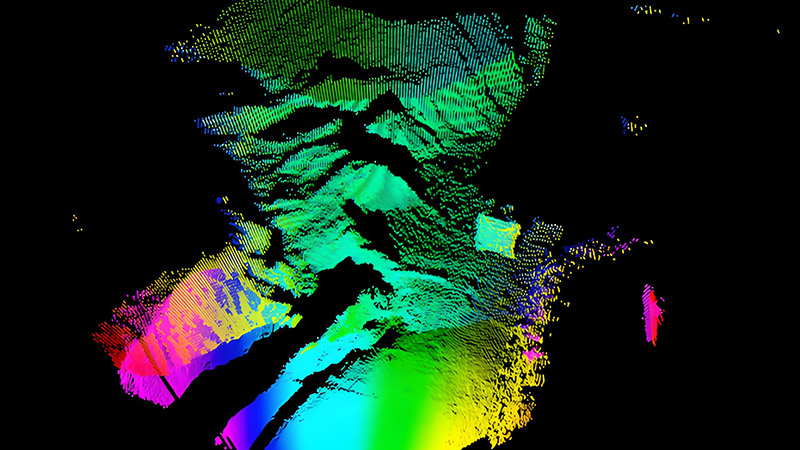

LiDAR technology uses laser pulses to capture precise topographic data, creating detailed 3D models of mine sites and surrounding areas. This information is essential for mapping ore bodies, assessing terrain, and planning mining activities. For example, LiDAR can be used to create accurate digital elevation models (DEMs) of mining areas, which are crucial for designing excavation plans and managing waste.

Optimizing Resource Extraction

Effective resource extraction requires a detailed understanding of the geology and topography of a mine site. LiDAR data supports this by providing accurate information on ore body distribution, rock formations, and surface conditions.

LiDAR can be used to create detailed maps of ore deposits and geological features, helping mining companies plan extraction methods and optimize resource recovery. By analyzing LiDAR data, companies can identify the most efficient extraction techniques, minimize waste, and reduce operational costs. This approach also supports the design of more precise drilling and blasting plans, improving overall efficiency.

Managing Stockpiles and Waste

Stockpile and waste management are essential aspects of mining operations, and LiDAR technology provides accurate data for managing these resources. LiDAR can be used to measure stockpile volumes, monitor changes in stockpile size, and assess waste management practices.

For example, LiDAR surveys can provide accurate measurements of stockpile volumes, helping companies manage inventory and plan for material handling. Additionally, LiDAR data can be used to monitor waste piles and assess the impact of mining activities on the environment. This information supports the implementation of effective waste management strategies and ensures compliance with environmental regulations.

Improving Safety and Risk Management

Safety is a top priority in mining operations, and LiDAR technology enhances safety by providing detailed information on mine infrastructure and potential hazards.

LiDAR data can be used to create accurate maps of underground and surface mine infrastructure, including tunnels, shafts, and support structures. This information helps in identifying potential hazards, assessing structural integrity, and planning maintenance activities. For example, LiDAR surveys can detect changes in ground stability, monitor subsidence, and assess the condition of support systems, reducing the risk of accidents and ensuring worker safety.

Supporting Environmental Monitoring and Management

Mining activities can have significant environmental impacts, and LiDAR technology supports environmental monitoring and management by providing detailed data on land use and terrain.

LiDAR can be used to monitor changes in land cover, assess the impact of mining activities on surrounding ecosystems, and manage rehabilitation efforts. For example, LiDAR data can be used to create accurate maps of affected areas, track vegetation regrowth, and assess the effectiveness of reclamation projects. This information helps mining companies implement sustainable practices and minimize their environmental footprint.

Enhancing Exploration and Site Selection

Exploration and site selection are critical for identifying new mining opportunities and assessing potential risks. LiDAR technology supports these processes by providing detailed data on terrain, geology, and land use.

LiDAR can be used to survey prospective mining sites, analyze geological features, and assess accessibility. This information helps mining companies evaluate the potential of new exploration areas, identify suitable sites for development, and make informed decisions about resource investment. By providing accurate and detailed data, LiDAR supports more effective exploration and reduces the risk of investing in unsuitable sites.

Future Trends and Innovations

The future of LiDAR in mining is promising, with ongoing advancements driving new applications and capabilities. Innovations include the development of more advanced LiDAR sensors, integration with other remote sensing technologies, and improvements in data processing and analysis.

For example, drone-based LiDAR systems offer the ability to capture data from difficult-to-reach areas and large mining sites more efficiently. Advances in machine learning and data analytics will enhance the ability to interpret LiDAR data, providing deeper insights into mining operations and supporting more precise decision-making.

Conclusion

LiDAR technology has transformed the mining industry by providing detailed, high-resolution data that enhances operational efficiency, safety, and environmental management. From improving mine surveying and resource extraction to managing stockpiles and ensuring safety, LiDAR offers significant benefits for modern mining practices. As technology continues to evolve, LiDAR will play an increasingly important role in optimizing mining operations and supporting sustainable practices.