Infrastructure inspection is crucial for maintaining the safety and functionality of public and private structures, including bridges, roads, and buildings. 3D LiDAR technology has emerged as a valuable tool in this field, offering precise and efficient methods for assessing infrastructure conditions and identifying potential issues.

Accurate Condition Assessment

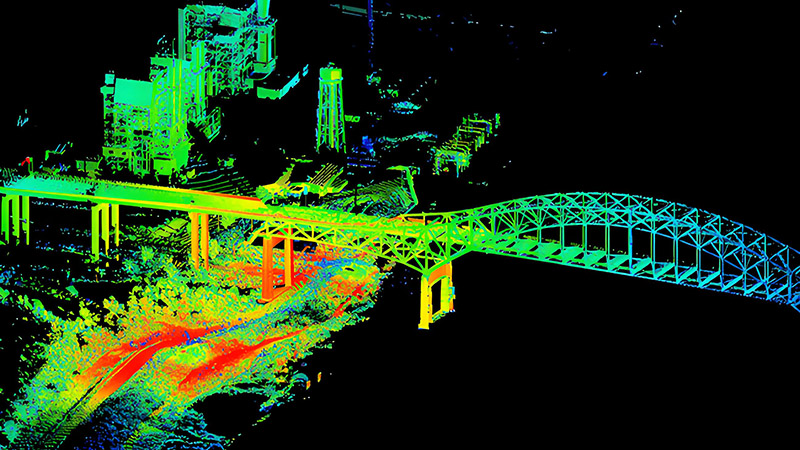

3D LiDAR provides detailed and accurate measurements of infrastructure, allowing for comprehensive condition assessments. By capturing high-resolution 3D data of structures, LiDAR can identify defects such as cracks, corrosion, or deformation that might not be visible through traditional inspection methods. This detailed information helps engineers evaluate the structural integrity of buildings, bridges, and other critical infrastructure.

For example, LiDAR can be used to inspect the surface of a bridge to detect signs of wear or damage. The technology’s ability to capture precise measurements ensures that any anomalies are detected early, enabling timely maintenance or repairs.

Efficient and Safe Inspections

Traditional infrastructure inspections often involve manual measurements and visual inspections, which can be time-consuming and hazardous, especially for large or hard-to-reach structures. 3D LiDAR streamlines the inspection process by allowing for remote data collection. Drones or stationary scanners equipped with LiDAR sensors can capture comprehensive data from a safe distance, reducing the need for manual inspection and minimizing safety risks for workers.

LiDAR’s efficiency also accelerates the inspection process. For large-scale infrastructure projects, such as highways or industrial facilities, LiDAR can quickly survey extensive areas and generate detailed 3D models, significantly reducing the time and cost associated with traditional inspection methods.

Monitoring and Maintenance Planning

In addition to initial inspections, 3D LiDAR is valuable for ongoing monitoring and maintenance planning. By regularly scanning infrastructure and comparing current data with historical scans, engineers can track changes over time and identify emerging issues before they become serious problems. This proactive approach helps optimize maintenance schedules and extend the lifespan of infrastructure assets.

For instance, LiDAR data can be used to monitor the settlement of roadways or detect shifts in bridge supports, allowing for timely interventions and reducing the risk of unexpected failures.

Conclusion

3D LiDAR is revolutionizing infrastructure inspection by providing accurate, efficient, and safe methods for assessing the condition of critical structures. Its ability to capture detailed 3D data enhances the detection of defects and supports proactive maintenance planning. As infrastructure continues to age and demand increases, 3D LiDAR will play a crucial role in ensuring the safety and efficiency of our built environment.